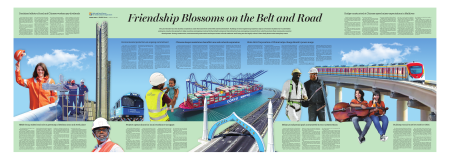

The past decade has seen fruitful cooperation under the framework of the Belt and Road Initiative. Building on their engineering expertise, legions of Chinese builders have undertaken extensive construction projects to help countries and regions involved in the initiative improve their infrastructure and regional connectivity in a bid to promote their social and economic development. During construction, environmental preservation and improvement of local residents' well-being are also highly valued. China Daily shares nine exemplary cases.

Combined efforts of local and Chinese workers pay dividends

On the Jhelum River in northern Pakistan stands the Karot Hydropower Station, the first hydropower project in the China-Pakistan Economic Corridor, which was put into commercial operation on June 29, 2022.

From 2015 to last year, thousands of builders from China and Pakistan worked on the project, striving for their shared goal.

Among them, Ren Zhimin, a technological manager for the Karot project, is a second-time participant in overseas hydropower projects.

His team consisted of 2,400 members during peak construction seasons, 78 percent of them local workers. How to train such a localized team to enable them to meet the technological quality standards was one of the challenges he faced.

Years of overseas project management experience gave Ren an edge in cultural integration and the training of local employees.

A key technician in his team, Saqib Khan, 28, who joined the project in 2017, is one of the best associates that Ren has mentored. "Khan is diligent, eager to learn and willing to take on any task," Ren said. "He is willing to see what he has done wrong, is open to criticism and will try and fix any mistake promptly."

Having worked in three positions within five years, namely technology management, supply procurement and quality control, Khan has grown into a versatile specialist who can handle tasks on his own.

Abdul Hafeez, in his late 50s, joined the project in 2015, working with China Three Gorges South Asia Investment as a senior manager responsible for maintaining relations with local governments and communities, as well as on-site labor management.

He said he has a "friendly and comfortable" relationship with his Chinese colleagues, and his closest friend is An Xiaobin from the project's land acquisition and resettlement department at the company.

When the project started in December 2016, a graveyard needed to be relocated for a spillway. An and Hafeez visited the community, communicated with related family members, and negotiated for a compensation mechanism. It took them just over two months to complete the relocation work. That was recognized as a successful case and it was posted on the International Finance Corporation website as an example.

HBIS Group takes lead role in greening of Serbian iron and steel plant

"The environment of this place is getting increasingly better."

That's how Ljubica Drake, environmental manager of HBIS Group Serbia Iron & Steel, described the lush premises of the first Chinese-acquired overseas fully-integrated steel enterprise, located on the site of the former Smederevo Steel Plant in eastern Serbia, about 45 kilometers from the capital city of Belgrade.

A veteran employee who joined the company in 2004, Ljubica was amazed at the company's green transformation. Before being taken over in 2016 by HBIS Group, a major Chinese steelmaker headquartered in Hebei province, the plant had seen its environmental facilities ground down to a virtual standstill.

A leader in the green development of China's steel industry, HBIS Group introduced its advanced production processes, technologies and concepts to HBIS Serbia, investing more than $200 million in making the production processes more efficient and environmentally-friendly. The efforts have paid of, promoting HBIS Serbia's across-the-board improvements, especially in automation, recycling, energy efficiency and green manufacturing.

With key facilities such as new sintering machines, furnaces and gas cabinets put into operation, HBIS Serbia is now on the fast track to green development. The project, prompted under the framework of the Belt and Road Initiative, has also fostered a growing friendship between Serbian and Chinese workers.

At sunset, Qi Fenglai, deputy head of the sintering workshop at HBIS Serbia, returned to his of ce after a busy day. Looking at a miniature terracotta warrior on his desk, a smile spread across his face. "This thoughtful small gift from my Serbian colleagues never fails to warm and brighten my days in this foreign land," he said.

As the employees from both China and Serbia were getting along with each other, mutual trust and respect have brought them closer.

Nenad Botic, a team leader in sintering machine operation at HBIS Serbia, expressed his admiration for the professional skills of the Chinese technical staff. In early 2023, Qi joined the team headed by Botic to fix their machines.

"The professional competence of the Chinese technical staff is estimable," Botic said, adding that he is confident that under their guidance, he will be able to reach their level one day.

Commissioned by the trade association of Chinese-invested Serbian businesses, a training program opened in January to improve member companies' media literacy, with HBIS Serbia taking a primary role in the program's operation. The event attracted executives from more than 40 companies to exchange and learn from each other.

In addition, the management of the company values its smooth integration into the local community and promotion of traditional Chinese culture. During this year's Spring Festival holiday, management members visited local residents, sharing China's folk customs with them and sending them festival wishes, with everyone immersed in a joyful atmosphere.

Environmental protection an ongoing commitment

Luis Albisu is an outstanding mechanical and electrical manager at the Kirchner-Cepernic hydroelectric power plant currently being built in Argentina by China Energy Engineering Group, aka Energy China.

In his 70s, Albisu exudes professionalism and a strong work ethic and often visits the construction sites to conduct personal inspections. Despite his senior management status, his vision goes beyond construction technology and production management as he is well aware of the importance of environmental protection.

Rather than being just a slogan, environmental protection needs to be put into practice, Albisu said. He presented a proposal to recycle wooden boxes made for shipping tools into furniture for local residents. The initiative has increased the reuse rate of the wood and scaled down consumption of natural resources while also reducing solid waste.

Albisu also proposed the use of separators to address the issue of mechanical waste oil. He actively sought solutions and introduced separators which protect the environment while saving the cost of waste oil disposal.

A dedicated team player, Albisu has committed himself to ecological protection and constantly calls on his colleagues to contribute to the environmental cause.

During the initial period of the power station's construction, he observed that some workers often casually discarded foam, plastic, wood and other waste materials that eventually ended up in the river or nearby neighborhood, causing pollution and damage to soil and water sources. After convincing the workers to stop littering, he now actively promotes environmental awareness by reiterating the importance of garbage classification.

Thanks to Albisu's unremitting efforts, environmental work at the power plant has been greatly improved and has won wide acclamation from the local community.

He has never given up his work or environmental efforts because of his age or physical condition, and his unwavering enthusiasm and perseverance have inspired those around him to increase their environmental awareness.

"It is everyone's responsibility to protect the environment," Albisu said. "Our generation should leave a better environment for the next one. If we don't protect the environment, then our descendants will inherit a lifeless world."

Chinese sleeper assistance benefits Laos rail network expansion

A railway construction project in Laos involving Chinese companies typifies the high quality of their work and success in overseas resourcefulness.

Among them, China Railway 15th Bureau Group Road-Bridge Construction Corporation Limited was the exclusive supplier of sleepers installed in the 422.4-kilometer Boten-Vientiane section of the China-Laos Railway, providing more than 801,200 regular sleepers in three types and nearly 260 sets of turnout sleepers in eight types.

Despite language obstacles, scorching temperatures and severe shortages of equipment and raw materials, in early 2020 the Chinese company spent 85 days establishing a standardized rail concrete sleeper manufacturing enterprise — more than six weeks ahead of schedule.

Quality control was strictly implemented in every step of the production procedures, ranging from raw materials and production to inspection. Each sleeper went through more than 30 production steps ahead of delivery, according to the company.

Building on a quality control team and a model workers' innovation studio for the project, the Chinese company achieved more than 20 technological innovations, which facilitated connection between different production processes and resolved the problems encountered.

Automatic control systems that were adopted in crucial steps in production, and an information technology-backed online platform in operation also helped improve work efficiency.

As well, by offering training to Lao employees, a great number of engineering management professionals and technical workers from the local community were recruited and they, in turn, assisted the company in increasing output and ensuring quality.

The project also opened the door to a better life for locals. When Suen, a Lao employee of the company, received her first pay, she said: "I had never expected that we, women workers, could take technical positions and earn the same high pay as men."

During the construction period, the Chinese company employed more than 200 Lao workers, of which 40 percent were women. And 90 percent of the project's front-line workers were from Laos.

Having learned cooking from Chinese chefs and his fellow workers, Somchit Soukkaseum, who previously worked as a kitchen assistant, was promoted to executive chef of the canteen established for the company staff. His creative integration of Lao and Chinese cuisine was a huge hit among his coworkers.

Green development is another salient feature reflected in the company's efforts to integrate into the local community during the project. "The project premises of China Railway 15th Bureau Group, a subsidiary of China Railway Construction Corporation, are beautiful, covered in greenness everywhere," said Bounthien Phimmaasone, head of a nearby village. "You could never imagine that used to be a barren landscape."

Other environmental efforts include the treatment of daily sewage and industrial wastewater, the installation of dust-removal, noise-reduction and vibration-damping facilities, the use of digital equipment, and recycling of construction waste for building roads.

State Grid Corporation of China helps charge Brazil's power surge

While 80 percent of Brazil's electricity is consumed in the more developed southern half of the country, its primary power plants are located in the north, over 2,000 kilometers away.

The growing demand for electricity in the vast South American country underlines the need for an "expressway" to transmit power generated in Belo Monte to southeast Brazil. This formidable undertaking has become possible with support from China.

The second phase of the Belo Monte ultrahigh voltage direct current transmission project, constructed by State Grid Corporation of China, addresses the need by transmitting power from the hydro-rich Amazon basin to the developed regions in the south and southeast.

Stretching more than 2,500 kilometers through 81 cities and five states, it is the world's longest ±800-kilovolt UHVDC transmission line, benefiting a population of 22 million along its route.

By February of this year, the project had cumulatively transmitted more than 160 billion kilowatt-hours of clean hydropower, equivalent to saving over 57 million metric tons of standard coal and reducing carbon dioxide emissions by some 159 million tons.

As the transmission line traverses rainforests, hills and grasslands that boast an abundance of wildlife, SGCC placed great emphasis on ecological preservation throughout the project. In strict adherence to relevant laws and regulations, the primary goal was to minimize the environmental impact on the local surroundings.

The project team established 13 animal rescue stations along the route, entered into contracts with 25 vegetation protection stations and hired more than 60 flora and fauna experts to ensure biodiversity protection during the construction period.

SGCC also conducted population surveys on 936 animal species, rescued 60 endangered plants and restored 1,100 hectares of vegetation in other areas.

In recognition of those efforts, the Belo Monte Phase II project was awarded the 2019 Best Commission's Brazilian Social Environmental Management Practice Award by Benchmarking Brazil.

The project team also attached great importance to advancing its social corporate responsibility initiatives to contribute to local cultural heritage preservation and the improvement of residents' well-being.

During construction, the team built or repaired over 1,970 kilometers of roads and 350 bridges, conducted archaeological explorations in 4,492 locations and unearthed 710 heritage sites and natural caves.

In addition, the team carried out 13 CSR programs, helping improve the quality of life for residents in disadvantaged communities by offering them vocational skills training.

Those efforts include support for the preservation of the Valongo Wharf Archaeological Site, Rio de Janeiro's 19th century slave disembarkation point, which has been listed as a UNESCO World Heritage Site.

The project team has also provided financial aid for the Mare do Amanha Orchestra, a community-based youth musical group in Rio de Janeiro, aiding in its development and participation in major events.

The orchestra, which has engaged more than 10,000 students from underprivileged communities, creates opportunities for many of its members to take charge of their own destinies.

Project opens doors for local workforce in Egypt

The first UWB College outside China was opened in the central business district of Egypt's New Administrative Capital on the eve of the 2020 Spring Festival.

The NAC is an urban community in Cairo Governorate and a satellite of Cairo City, and the CBD project is contracted to China State Construction, which is also a co-founder of the college.

Named for Lu Ban, a legendary civil engineering master in ancient China who was renowned for his exquisite craftsmanship, the college features a mentor system designed to help Chinese companies foster skilled local workers in countries and regions involved in the Belt and Road Initiative.

Among the beneficiaries is Ebrahim Abdel Hamad, who hails from a remote rural area in Aswan Province. He was overwhelmed by the activity when he arrived at the construction site to begin work, but was determined to make good. "I wanted to go all out in performing my job, but the dense network of pipelines and cables confused me, leaving me at a loss of what to do," he recalled.

As the project progressed, the college encouraged and helped Hamad and other locals improve their vocational skills through hands-on instruction, support and care. Hamad proved to be a keen learner. He volunteered to assist senior Chinese workers, and through that effort received valuable vocational training.

Hamad eventually learned to work independently on the site by referencing blueprints, and with further training and practice, he was able to pass along his knowledge to other local workers.

"The project has provided me with an opportunity to make a living building on my skills," said Hamad, whose formal education was limited to primary school. "When I save enough money, I want to use the techniques I have learned here to build a big house for my family."

The increased income has greatly improved his life. During his vacation, Hamad returned home and introduced some Chinese colleagues to his family and friends. "Eight of my fellow villagers were so envious and impressed that they followed me back to the project seeking job opportunities," he said.

Hamad's success in going from being a laborer who carried equipment and construction materials to becoming a team leader is not unique.

The project has attracted laborers from all over Egypt, and many villagers like Hamad have benefited from projects under the BRI framework.

Currently, the CBD project has cooperated with more than 300 Egyptian companies, providing training for industrial workers, promoting improvement in management skills and helping nearly 30,000 laborers find employment.

Belarus industrial park committed to eco-preservation

Great Stone Industrial Park, a China-Belarus cooperation project endorsed by both governments, provides an exemplary approach to harmonious coexistence between humans and nature, where rare plants and animals are protected and a pristine environment is preserved.

The green development path of the industrial park, located in a suburb of Minsk, capital of Belarus, can be traced back to the planning phase when its builder, China CAMC Engineering Co Ltd, aka CAMCE, a subsidiary of China National Machinery Industry Corporation, conducted preliminary research into water sources, animals and forests.

From the very beginning, a founding principle of the industrial park was to preserve as many ecological functional areas as possible and ensure the project's development in harmony with the environment, according to CAMCE.

Known as the "Land of a Thousand Lakes", Belarus has strict environmental regulations that required adjustments to the industrial park's design and construction.

For instance, rainwater and snow water are required to be treated — a standard much higher than in China, CAMCE said. Also, the quality standard for treated wastewater had to be raised to a higher level for aquaculture.

Despite prohibitive expenditures to ensure compliance, the Chinese builders respected and conformed to the high environmental standards.

The Belarusian environmental regulations also include stipulations for construction materials used for house exteriors and the purpose of properties.

Among the tracts of the park land where property development is banned is an area where nearby villagers bury dead animals. Another property-banned area was discovered to contain rich mineral resources, so it was preserved for future exploration.

A large tract of land in the project has been earmarked for green coverage, so forests inside the park and in the surrounding area have been preserved. In particular, to prevent pollution of rivers running across the industrial park, CAMCE's designers established water source conservation areas and hygiene protection belts in the development plan.

The preservation of 15 nearby villages has also been factored into the Chinese planners' consideration. CAMCE made allowance for a 300-meter-wide green belt to separate the villages from the industrial premises in the park to ensure environmental stability.

In addition, the Chinese company has constructed roads and infrastructure to provide water, electricity and gas to villages that previously had no such basic services.

Bridge constructed at Chinese speed raises expectations in Maldives

Famed as a tourist resort, the Maldives, a country consisting of a group of atolls in the Indian Ocean, had always longed for a cross-sea bridge to facilitate transportation.

The dream came true when the China-Maldives Friendship Bridge, linking the islands of Male, Hulhule and Hulhumale, was completed by Chinese builders five years ago.

The bridge has improved road connectivity and access to the international airport on Hulhule.

One of the most crowded cities in the world, Male covers an area of 1.8 square kilometers yet is home to more than 150,000 residents, roughly one-third of the country's population.

No wonder the construction project grabbed the attention of the country when it was opened to traffic in 2018.

Back then, Imthiyan Hamdhy, a young taxi driver shuttling through the streets and alleys of the capital city every day, paid close attention to the project's progress.

After learning that the bridge was soon to be put into use, he drove to an observation platform near the bridge construction site every day for two straight weeks to see how the work was progressing.

"It is really uplifting," he said prior to the opening of the bridge. "I will be able to pick up passengers from Male and take them across the bridge to Hulhule Island."

Abdullah Among, an electrician in his 50s who works at the Maldives airport and lives in Male, was also among the multitudes that looked forward to the opening of the bridge.

He had to spend around two hours commuting from home to work every day. "I had to take a ferry and then a bus to get to my workplace," he said, gazing at the bridge under construction in the distance. "When the weather was rough, the ferry rides could be really dangerous and physically unendurable."

He took photographs of the bridge in various stages of construction using his cellphone. "Its construction was so fast, fast, fast," he said, trying to emphasize how quickly the bridge was completed. "Without Chinese builders, the bridge would not have been completed until six or seven years later," he said.

Construction of the bridge also led to the upgrading of the roads in Male, transforming the previously brick-paved streets and alleys into smooth and spacious asphalt roads. "The bridge and roads provide new hope for our country," he said.

Amira Latheef, an executive in charge of foreign human resources at CCCC Second Harbor Engineering, said, "My father is proud of my work on the project team."

"Despite occasionally feeling some pressure, my working environment is pleasant. My colleagues are friendly and ready to help," she said.

While working with her Chinese colleagues, she found them "diligent and focused" at work. "The majority of the Chinese working on the bridge were not with their families, but leave their homeland to work hard alone abroad. Yet I never heard them complain about the toughness of their work — their work always came first in their minds."

She said that if Maldivian people themselves can build a bridge, she hopes to be involved and bring the advanced knowledge she has learned to the industry, so she can help make her homeland more prosperous.

Building mutual trust key task for CREC

The Jakarta-Bandung High-Speed Railway, which was opened to traffic in Indonesia on Sept 7, is a signature construction project under the Belt and Road Initiative, promoting both regional connectivity and people-to-people exchanges.

China Railway Group Limited, aka CREC, a co-builder of the project, was well aware of how to create a friendship path to win the hearts of local residents.

When China Railway No 4 Engineering Group, a subsidiary of CREC, planned to start establishing a temporary production facility in Cileunyi town to provide sleepers and other components for the railway project, the news caused consternation among local villagers. They worried that the premises would become an obstacle to transportation, and the rural paths would be unable to be recovered after the project, although the bumpy paths were already in bad repair.

Due to the lengthy rainy season each year, spanning from October to May, heavy rainfall had made the village paths muddy and potholed.

After spending half a year in communication, the Chinese company reached an agreement with five nearby villages, providing a solution that freed them of their misgivings once and for all.

The company built a total of 1.8 kilometers of 2-meter-wide roads for the villages while offering financial aid. The new roads have standard protective barriers, making travel safer and more convenient.

The move won the trust of the villagers, who, in turn, became more supportive of the temporary production facility and the railway project.

CREC said it is consistent in valuing the wellbeing of local communities in its overseas projects, and it is going to great lengths to advance more projects that can benefit local residents.